Flexibility and power

Cursor engines are Stralis heart. An engine family which has already widely proved its qualities in terms of performance, consumption and reliability given its many characteristics:

• single pump-injector with injection pressure up to 2000 bars

• head camshaft

• 4 valves per cylinder

• under-basement and single cylinder head to ensure higher rigidity

• decompression engine brake

• time and fuel quantity electronic control for each cylinder

• variable-geometry turbine for a prompt response in any rpm conditions.

For this reason Cursor power is always reliable, as shown by the torque curves which reach the maximum value below one thousand revolutions and keep it for the whole use range.

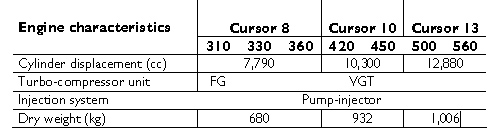

In the versions by 8, 10 and 13 litres, these engines have power range from 310 to 560 HP and max torque values up to 2,500 Newton/metre.

Powerful and reliable, Cursor engines have been designed to ensure not only excellent performance, but also low running costs, in addition to a higher driving comfort given their extraordinary flexibility.

Durability and fuel economy

Stralis is designed to offer an overall low ownership cost to the customer as a result of the reduction of the vehicle two main cost items, i.e. maintenance and fuel. Stralis reduces maintenance costs minimizing downtime with prolonged oil change intervals (150,000 Km) and through a quick and accurate diagnostics onboard.

Cursor Euro 5 engines are a reference point in terms of torque, life, maintenance and operating costs: they consume 2 to 5% less compared to the already economic Euro 3 versions.

Gearboxes, front and rear axles

In addition to the engines, a wide range of gearboxes, front and rear axles ensure the optimal correspondence between the kinematic chain and the use missions, thus enhancing the vehicle productivity.

To deliver the whole power of Cursor engines to the drive wheels, Iveco uses top market components and technologies.

The gearboxes are supplied in a wide range of versions:

• mechanical - ZF with 9 or 16 speed gears (with servoshift to ensure comfortable gear shifting);

• automatic - Allison (specifically for “stop and go” missions);

• EuroTronic fully-automated with 12 gears, known and appreciated for its ergonomics and reliability on Stralis and Trakker range.

The 9-speed gearbox 9S1310TO with “simple H” is installed on models with engines Cursor 8, 310 and 330 HP; the automated gearbox Eurotronic 12AS1420TD is installed on models with Cursor 8, 310 and 330 HP. The manual gearbox with 16 gears is available also on models with Cursor 13 560 HP.

The automatic logics applies the principles at the basis of economic driving, which means selecting the ideal gear ratio, protecting the gearbox against over-revving, safeguarding the clutch life, reducing consumption and noise.

Arvin Meritor and Iveco rear axles are extremely robust and require limited maintenance. They are supplied both in the simple and dual ratio version to ensure maximum safety and reliability also in the most demanding missions.

Reliability and safety of a top-class truck

Chassis

The life of a commercial vehicle, and especially heavy, depends first of all on the chassis capacity to bear intense and prolonged strains without any fatigue. Iveco is famous for its robust chassis, and Stralis chassis is no exception. The side members, with double bottleneck with U section connected by nailed crossbars, are made with a special type of steel Fe E 490 with high yield level and with thickness between 6.7 mm to 7.7 mm.

Electric system

Obviously, the mechanical robustness alone is not sufficient to ensure a lasting efficiency without a reliable electric and electronic system.

For this reason Stralis wiring, in the cabin and on the chassis, is made with CAN-Bus architecture and Multiplex technology: a solution which enables highly efficient communication among all the control units of the main vehicle components and sensors.

Instead of the traditional wires where just one electric pulse usually passes through, Stralis uses Multiplex wires through which it is possible to transmit multiple signals simultaneously. The reduction of the number of wires onboard (- 45%) and of the connection points means higher system reliability, an elegant and clean layout on the chassis and a significant fall in time and service costs.

Braking system

Safety also means a technologically advanced braking system. The whole Stralis range is equipped by factory with a top-quality fan disc system and EBS electronic control.

The EBS function is to optimize the braking action: by pressing the brake pedal, the driver sets an acceleration value and the electronic control unit of the braking system regulates the speed reduction parameters:

• it adjusts the pressure inside the vehicle brake cylinders;

• it regulates the trailer (if any) brake supply pressure as to obtain an even distribution of the braking force between the axles;

• it operates the decompression brake called ITB (Iveco Turbo Brake).

For the missions on roads with high gradients, Stralis is equipped with the second generation ZF Intarder which offers a wider range of rpm for the maximum slowing down torque and reduces free power absorption, thus improving consumption.

Active safety

The whole Stralis range is equipped with electronic stability program - ESP.

In addition to ESP, it is possible to fit on the vehicle a set of state-of-the-art devices which ensure its active safety:

• the Hill Holder helps the driver start up the vehicle on slopes preventing the vehicle spontaneous moving back for some seconds;

• the ACC (Adaptive Cruise Control) is a system which helps the driver keep the safety distance from the vehicle travelling in front of it by automatically operating the Turbo Brake, the Intarder and finally the service brake in this order;

• the Lane Departure Warning System signals when the vehicle is crossing the lane centre line without turning on direction indicators.